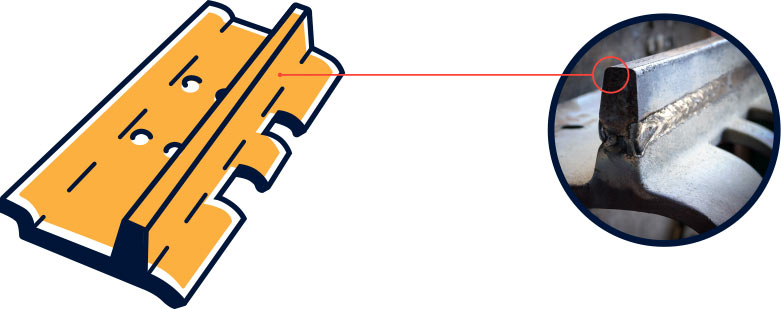

Grouser Bar Pikeun Bulldozer na Excavator

A grouser bar mangrupakeun komponén logam ilaharna kapanggih dina mesin beurat, kayaning bulldozers na track loaders. Ieu napel na sapatu lagu tur mantuan ngaronjatkeun traction na cekelan ku biting kana taneuh. Bar Grouser penting pisan pikeun ningkatkeun kinerja mesin dina rupa bumi anu nangtang, sapertos taneuh leupas atanapi lamping anu lungkawing. Éta datangna dina rupa-rupa wangun sareng ukuran pikeun nyocogkeun kana aplikasi anu béda sareng tiasa digentos nalika lungse pikeun ngajaga fungsionalitas anu optimal.

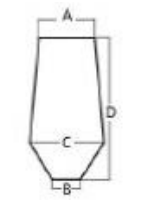

| BAGIAN | Hiji mm | B mm | C mm | D mm | Panjangna (mm) | W (kg) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25" | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25" | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25" | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

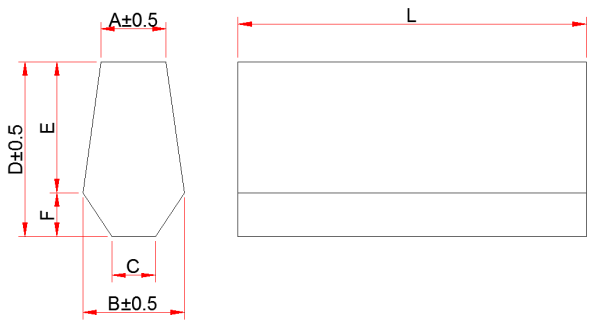

bahan béda pikeun rujukan

Bahan: 65Mn Teu karasa: HB300~HB320 Panjangna tiasa disaluyukeun, maksimal 6000mm

| Nomer bagian | A | B | C | D | E | F | L | W (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0,4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Bahan: 40Cr Karasa: HB500 Casting sareng Perawatan Panas diperyogikeun.

| Nomer bagian | A | B | C | D | E | F | L | W (KG) |

| EKOR 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| ACORK 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORK 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| KORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Bahan: 42CrMoNi Teu karasa: HB500-550 Casting sareng perlakuan Panas diperyogikeun.

| Nomer bagian | A | B | C | D | E | F | L | W (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |

- Wangun mana anu paling cocog sareng pola pamakean anjeun?

BAR LENGKAP

- Pola pakean malah sapanjang jalan

- Sapatu dipangkas pikeun permukaan datar

- Gawéna ogé kalawan welders otomatis

BAR ngajalin

- Pola maké buleud kalayan ujung anu parah

- Ngaleungitkeun kabutuhan pikeun motong

- Tungtung bar dipotong dina sudut 45 derajat pikeun résistansi péngkolan kirang sareng dukungan tambahan

- Tungtung bar hooked dirancang pikeun nyocogkeun sapatu lagu kalawan maké parna on edges

- Idéal pikeun sapatu lagu dilas di sawah

BAR melengkung

- Pola makéna rada buleud

- Ngaleungitkeun kabutuhan pikeun motong

- Bentuk bar melengkung ngirangan jumlah las eusian anu diperyogikeun

- Idéal pikeun sapatu lagu dilas di sawah

BAR BEVELED

- Pola pakean malah sapanjang jalan

- Sapatu dipangkas pikeun permukaan datar

- Tungtung bar dipotong dina sudut 45 derajat pikeun résistansi péngkolan kirang sareng dukungan tambahan

- Gawéna ogé kalawan welders otomatis